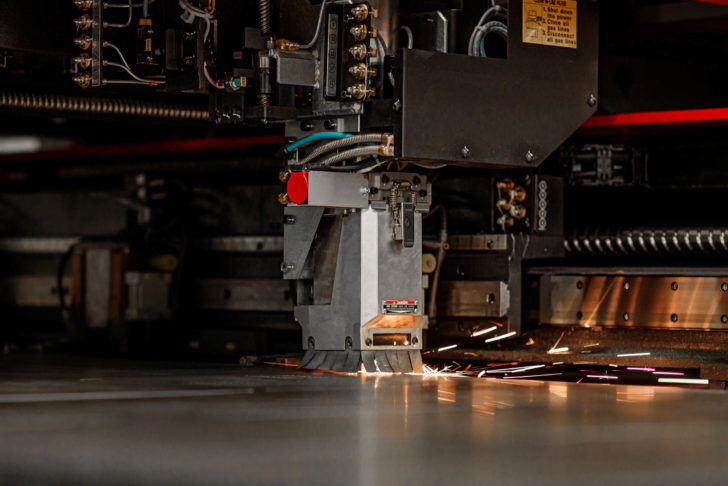

Laser Cutting

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

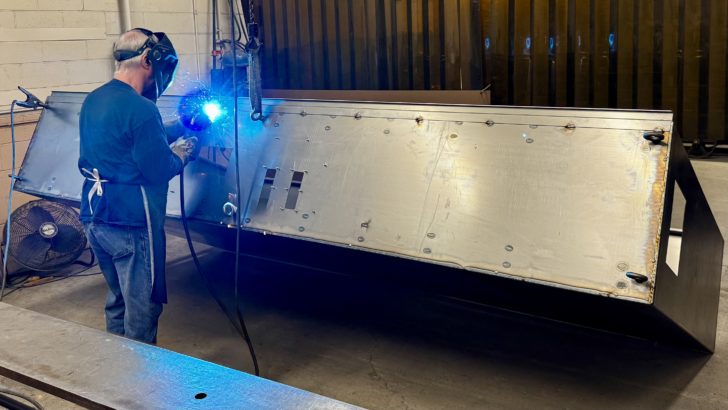

DAWSON’s highly skilled team extend their expertise to metal cutting, bending, welding, and finishing, creating close tolerance, custom metal fabrications that meet or exceed your expectations.

DAWSON has a long history of successfully working with industries requiring complex metal fabrication, with particular expertise in closely collaborating with electronics, marine, medical, power generation, rail car transportation, and retail industries.

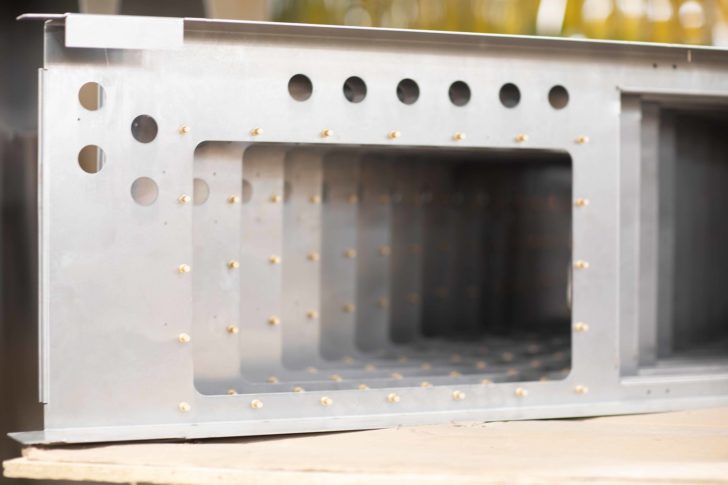

DAWSON specializes in the manufacturing of cabinets, enclosures, and kiosks; decorative highly cosmetic custom metal finishings; discrete components made from sheet metal; precision frames and weldments; precision sheet metal components; and powder coated sheet metal products to meet your specification. We are your premier custom metal fabrication experts!

At DAWSON, we utilizes a number of the latest software and cloud based platforms in-order to best support our customers. From 3D CAD software to online CRM, DAWSON harness the latest technology to stay organized, compatible and competitive for our customers.

The Proven Solution for 3D Design & Product Development

3D Design, Engineering & Construction Software

Design and Drafting Software trusted by millions

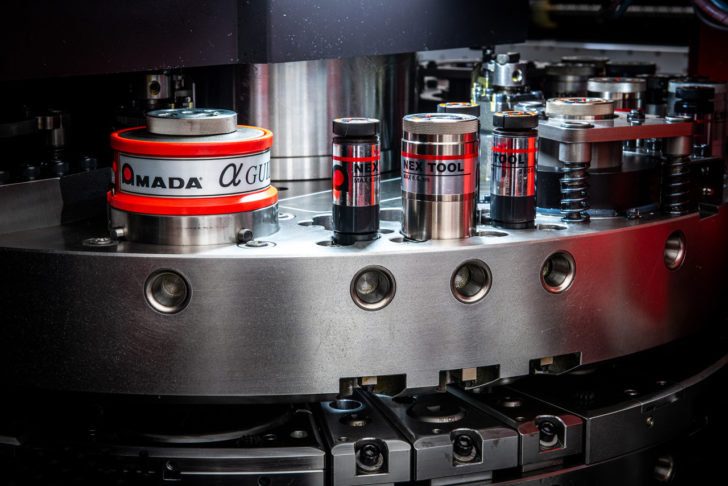

AMADA Software Solutions - Ensuring “Right First Time” Production

Cincinnati Brake Software

Solutions for Manufacturing

Fabrication Software Suite to Drive Your Manufacturing

Haeger Offline Programming Software

Work Platform | Made For Work, Designed To Love

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

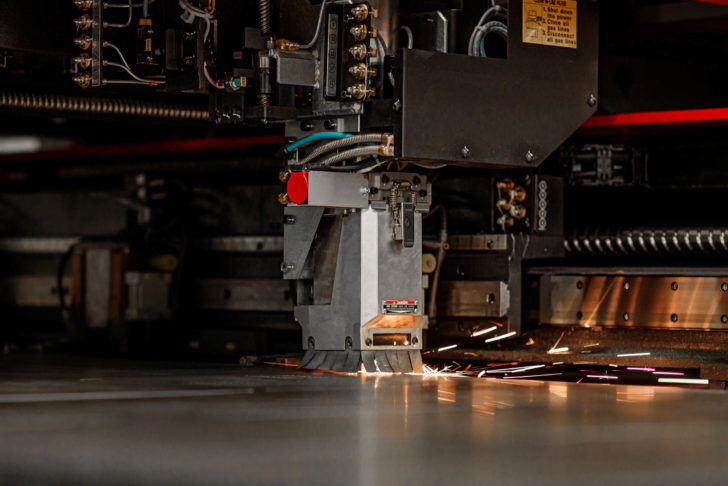

Complex sheet metal component shapes are achieved through precise, programmed machinery.

DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.

A full range of mechanical fastening options are available to achieve your project’s requirements.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

One of our many welding fabrication techniques are applied to fuse your creation together.