Machining

Our in-house, high-performance machine tools, meets the precise requirements needed to produce the high quality parts you demand.

DAWSON utilizes the HAAS VF5-XT as a solutions center to fabricate non-sheet metal components. The HAAS VF5-XT has the capacity, features, reliability and speed, to efficiently produce high-quality parts you demand.

With a 60″ x 145″ work area, DAWSON’s MultiCam 5000 Series Routing Table can route any non-ferrous materials at high-speeds with offline programmed repeatable accuracy.

Other Services

DAWSON Engineering Team

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

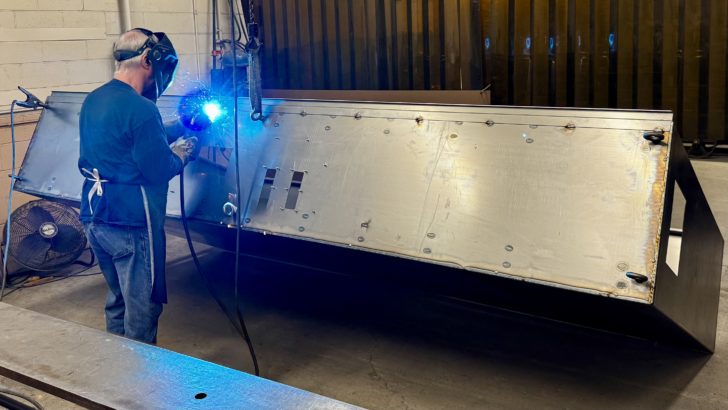

Welding

One of our many welding fabrication techniques are applied to fuse your creation together.

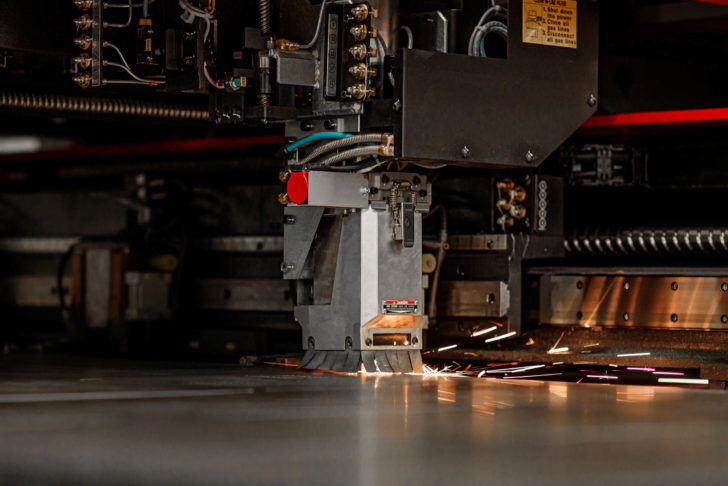

Laser Cutting

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

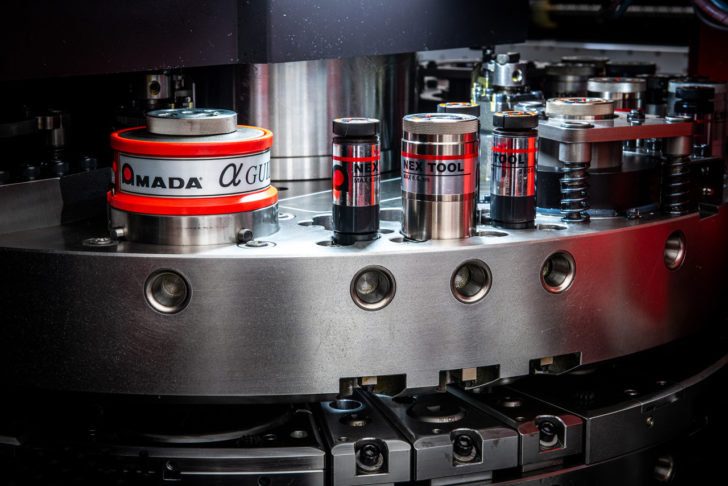

CNC Turret Manufacturing

Complex sheet metal component shapes are achieved through precise, programmed machinery.

Quality & Inspection

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.

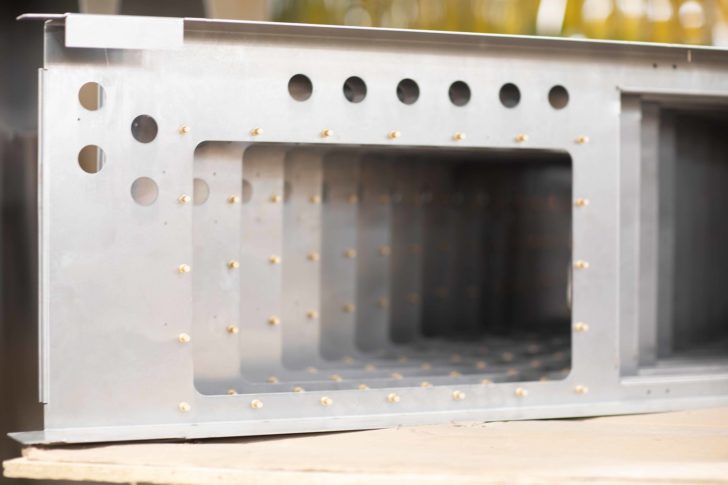

Hardware Insertion

A full range of mechanical fastening options are available to achieve your project’s requirements.

Cellular Manufacturing

DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.

Brake Forming

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.