DAWSON Engineering Team

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

Inside the DAWSON Quality Lab and on the production floor, reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.

DAWSON has a system in place for achieving and maintaining the desired level of quality for our customers. Acceptance criteria for products are defined in appropriate subordinate documentation.

Reviews, inspections, and tests are conducted at appropriate stages to verify that the requirements have been met. This is done before products are released or services are delivered.

To achieve total customer satisfaction by continuously improving our processes in order to provide quality products on time, and at a fair price.

DAWSON utilizes special equipment to thoroughly review products for quality, including but not limited to the following:

The 6-axis ROMER Absolute Arm is designed for highly-accurate tactile measurements on countless types of workpieces. It allows for reliable touch probe measurement and inspection of nearly anything. Since the ROMER Arm is portable it allows for inspection of large components that may not be practical to measure in the Quality Lab.

Inside the DAWSON Quality Lab is our Helmel Check Master Bridge CMM. This piece of equipment is used for checking precision components and/or assemblies.

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

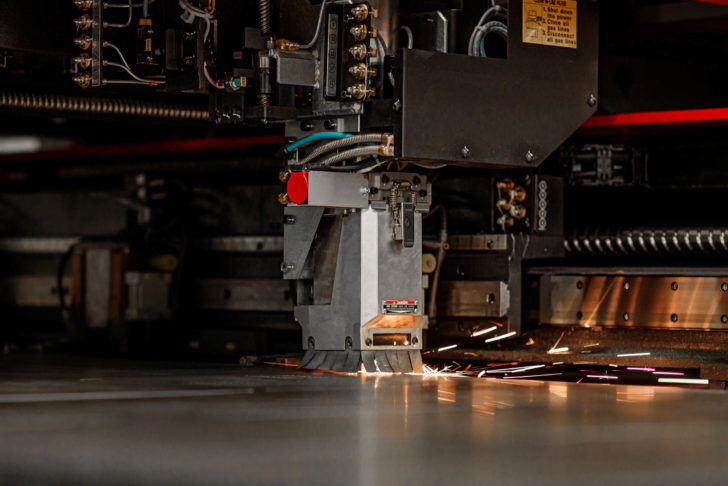

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

Complex sheet metal component shapes are achieved through precise, programmed machinery.

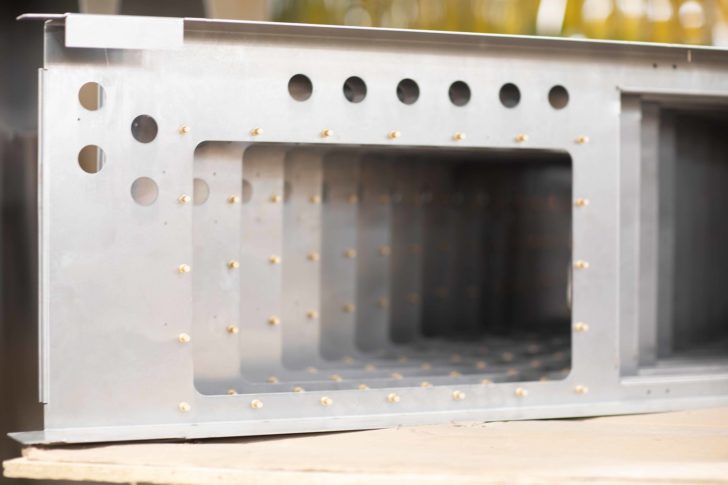

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

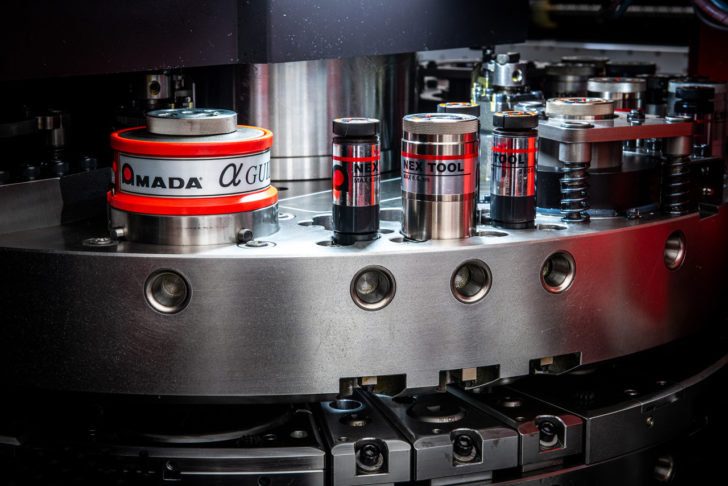

A full range of mechanical fastening options are available to achieve your project’s requirements.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.

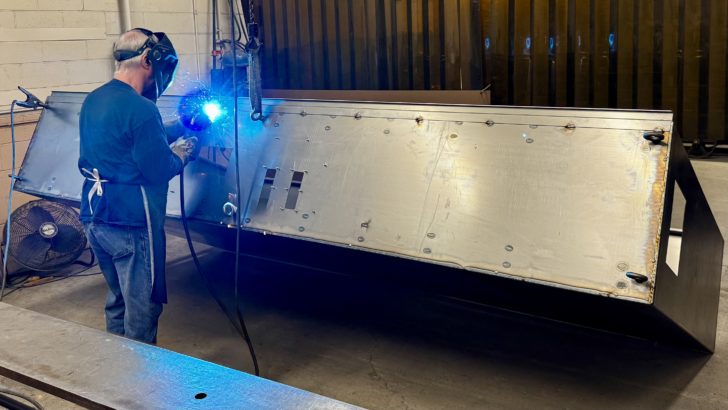

One of our many welding fabrication techniques are applied to fuse your creation together.