DAWSON Engineering Team

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

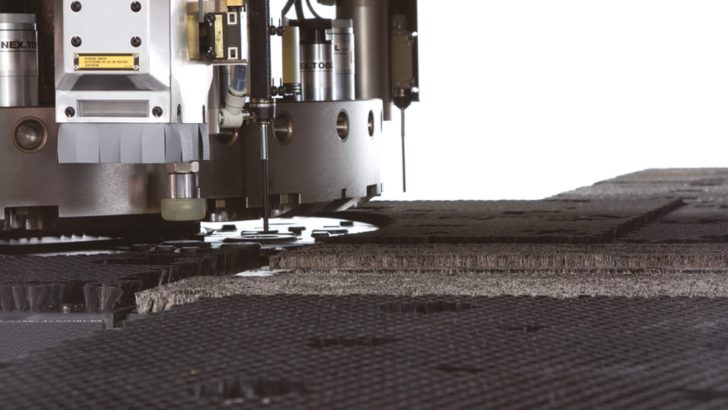

DAWSON’s Amada LC2012 is a versatile and accurate Punch and Laser Combination System and is another example of DAWSON’s ongoing commitment to improved efficiency and utilization of up-to-date technology.

The C1 gives DAWSON the ability to laser cut and turret punch on the same machine, reducing costs by eliminating the need for secondary manufacturing operations.

The Amada Pega 357 allows DAWSON to punch large features, such as louvers, up to 4.5″

This state-of-the-art Punch and Laser Combination System is another example of DAWSON’s ongoing commitment to improved efficiency and utilization of up-to-date technology. The C1 gives DAWSON the ability to laser cut and turret punch on the same machine, reducing costs by eliminating the need for secondary manufacturing operations.

The C1 delivers an excellent cutting quality with a laser output of 2500 Watts. In addition to laser cutting, with DAWSON’s extensive tool library the C1 is capable of a multitude of 3D punching and machining applications (operations, features?) such as:

• Precision tapped extrusions and holes in English and Metric threads

• Forming of small features (such as bent flanges)

• Lances

• Half shears

• Embosses and Collars

• Louvers

• Countersinking

• Counterboring

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

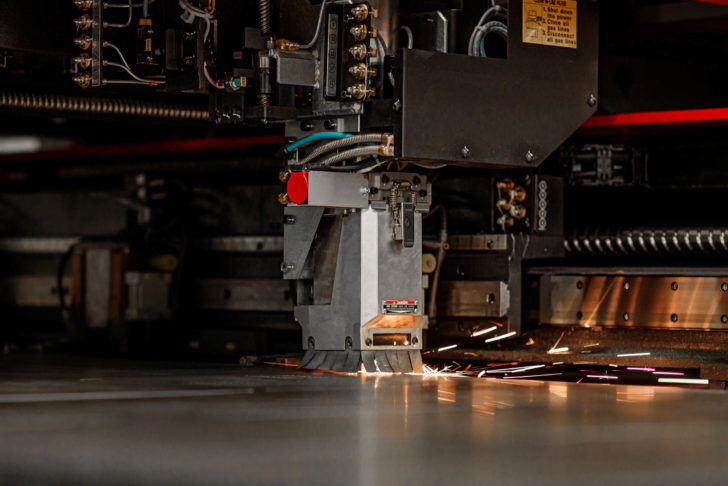

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

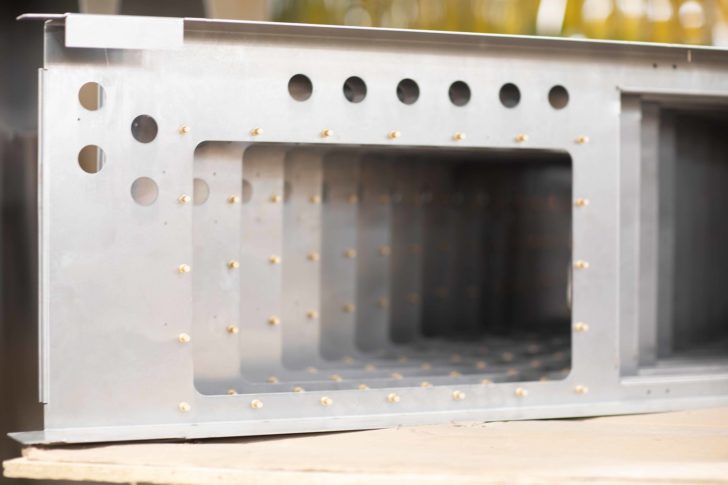

A full range of mechanical fastening options are available to achieve your project’s requirements.

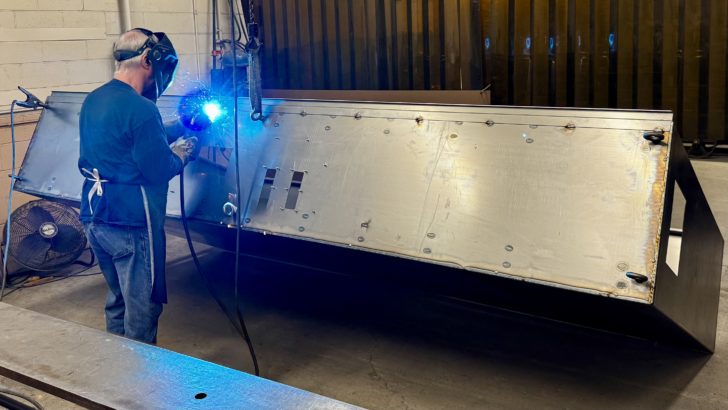

One of our many welding fabrication techniques are applied to fuse your creation together.

DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.