DAWSON Engineering Team

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

DAWSON’s investments span to the latest laser technologies. Our in-house, high-speed laser equipment, has the versatility to achieve the best solutions for your short-to-long running projects.

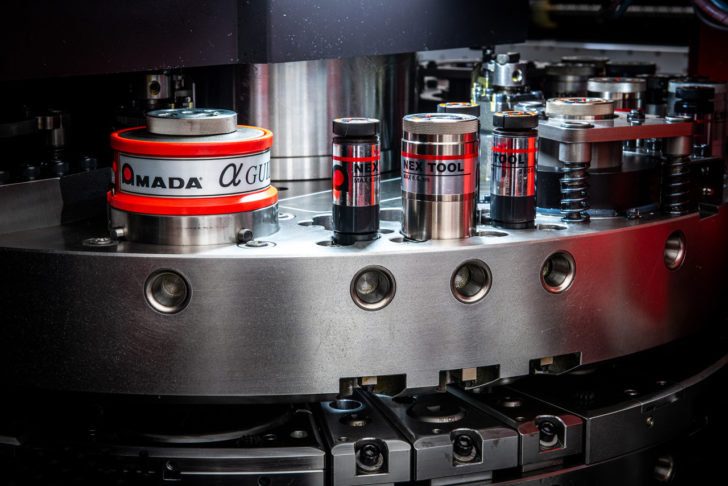

Our Amada C1 Combo laser combines modern forming and tapping abilities with laser precision at open-ended lengths.

Our AMADA ENSIS 3015 Aj Fiber Laser, is capable of cutting thin materials up to four times faster than conventional CO2 lasers, and producing high-quality parts on materials up to 1” thick Hot Rolled Steel.

With an automated nozzle changing station and load/unload system, DAWSON’s Ensis laser is able to run unattended at the full speed of the equipment.

With DAWSON’s laser technology we are able to cut a wide variety of materials and thicknesses.

DAWSONhas full sheet stock cutting capabilities to manufacture your short to long-running project. We understand that no two customer’s needs are exactly alike and a dedicated DAWSON engineer will collaborate with our team and the customer to recommend the best solution for manufacturing your product.

Whether it is expediting work to the shop or running “lights out”, the Ensis is extremely versatile. This high speed programmable fiber laser can cut thin materials up to 4 times faster than conventional CO2 lasers and produce high-quality parts on materials up to .875” thick. Cost-saving features include:

• The MPL Automated Load/Unload System that can hold up to 2000 lbs. of sheet stock.

• A multi-axis helical rack and pinion drive system for higher acceleration and rapid traversing.

• An LCD color touchscreen which allows for ease of operation by all users.

• A network connected control for fast and easy transfer of offline generated programs.

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

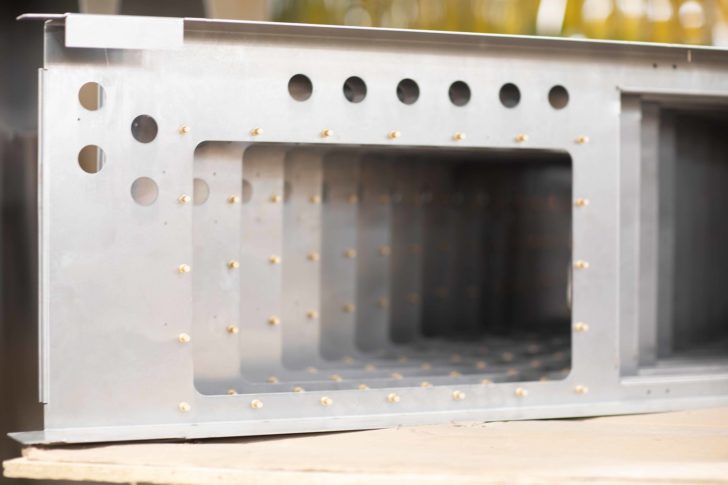

Complex sheet metal component shapes are achieved through precise, programmed machinery.

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

A full range of mechanical fastening options are available to achieve your project’s requirements.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

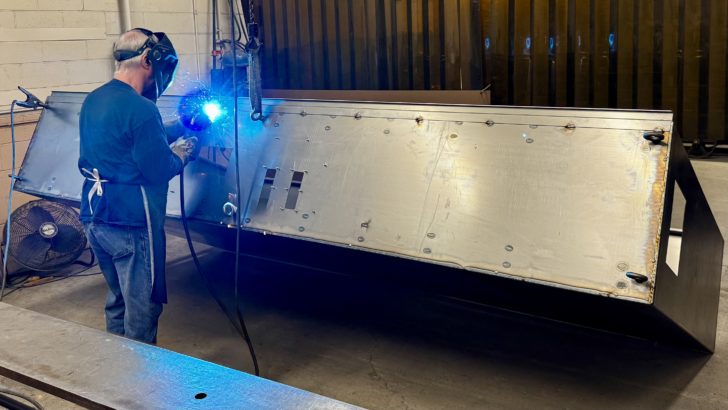

One of our many welding fabrication techniques are applied to fuse your creation together.

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.

DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.